Cracked B230 cylinder, best way to prevent in future

Postat: tis maj 17, 2016 2:46 pm

First, the engine setup:

E-85

2.5L 16v FS324 cams HX-52, nitrous(why not), ~9:1 compression ratio (or possibly lower). 96.5mm bore size.

block is 1995 b230f

Running about 35psi when it broke, Ethanol percentage has been steady at 75% for the past tank and a half of fuel, about 17 degrees of ignition timing up top(crept up to that via tuning at the track). ~.78 lambda. Max rpm's 8100. Stock valve size, but ported head. (not that that matters for this)

Car traps 133mph off the spray, and 142mph on the spray

Block was pinned.

When it likely cracked: 34psi, 17degrees, and ~.95 lambda. I think injector, because only #3 showed any signs of trouble. 1,2,4 all looked good, plugs looked good when the head came off.

I had an issue (suspect faulty injector) sunday at the race that resulted in problems with the #3 cylinder, with it finally cracking up to the deck (don't know how far down the crack goes, haven't gotten the block out of the car). In reading other threads here on Savar, I've noticed two things:

96.5mm bore size may be "too big" for the power level I'm at and the power levels I'm hoping to get to, and

Pistons did not have a 'full skirt'

So, my question is this: Is it better to sleeve a block, perhaps to a slightly smaller bore size (say, 94 or 95mm) and retain the cooling system and perhaps run a little tighter piston to wall clearance, OR

fill the block with hard-blok and run whatever pistons fit with minimal machine work to the bores? I've seen talk of 2-3cm from the top, with tubes for coolant, but I'm having a hard time picturing this. Are there any photos of this process?

Is there anything else I need to consider/do with the block? It may eventually get to 900-1000hp, but I'm in no rush to see those numbers yet.

The engine went out on a high note, I outran an F1x procharged 2015 viper at a roll race event

https://youtu.be/1tuFK_EGNGc

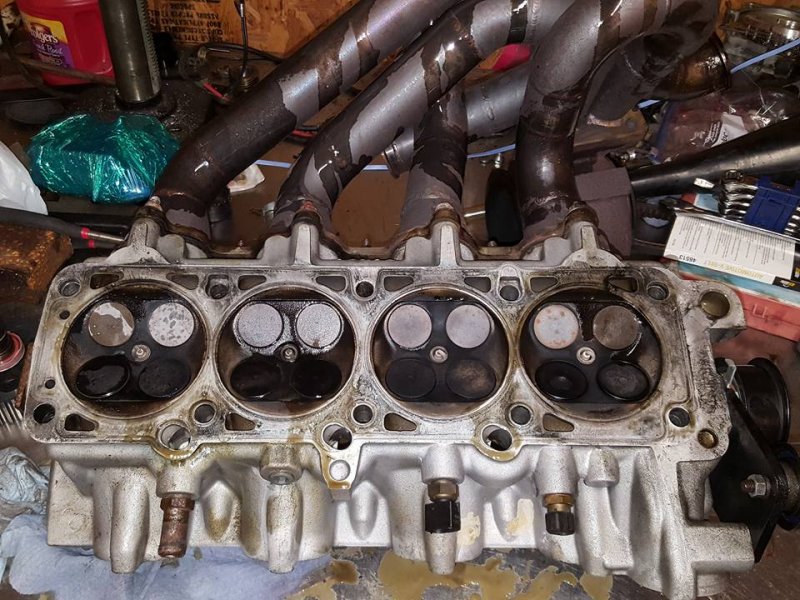

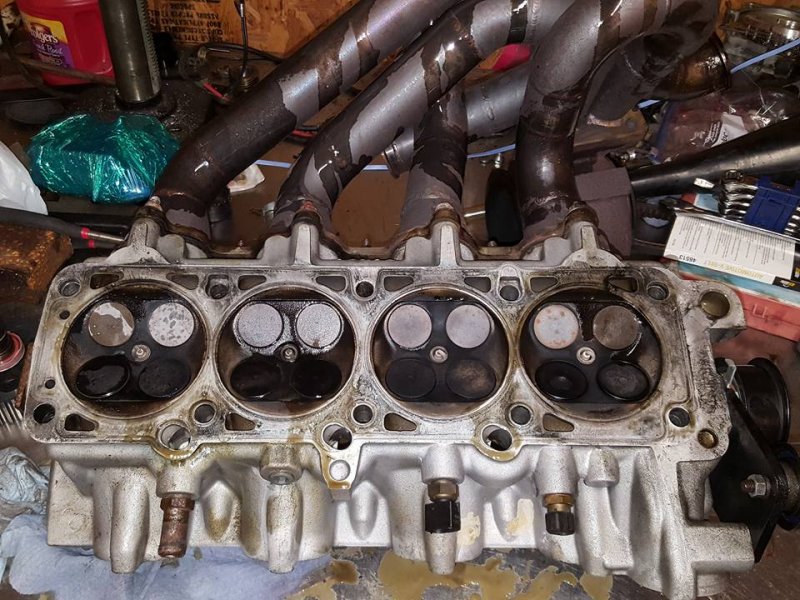

only have a few pictures right now, perhaps something else jumps out.

(and yes, no roll cage. that's also on the summer project list along with switching to a wagon chassis)

E-85

2.5L 16v FS324 cams HX-52, nitrous(why not), ~9:1 compression ratio (or possibly lower). 96.5mm bore size.

block is 1995 b230f

Running about 35psi when it broke, Ethanol percentage has been steady at 75% for the past tank and a half of fuel, about 17 degrees of ignition timing up top(crept up to that via tuning at the track). ~.78 lambda. Max rpm's 8100. Stock valve size, but ported head. (not that that matters for this)

Car traps 133mph off the spray, and 142mph on the spray

Block was pinned.

When it likely cracked: 34psi, 17degrees, and ~.95 lambda. I think injector, because only #3 showed any signs of trouble. 1,2,4 all looked good, plugs looked good when the head came off.

I had an issue (suspect faulty injector) sunday at the race that resulted in problems with the #3 cylinder, with it finally cracking up to the deck (don't know how far down the crack goes, haven't gotten the block out of the car). In reading other threads here on Savar, I've noticed two things:

96.5mm bore size may be "too big" for the power level I'm at and the power levels I'm hoping to get to, and

Pistons did not have a 'full skirt'

So, my question is this: Is it better to sleeve a block, perhaps to a slightly smaller bore size (say, 94 or 95mm) and retain the cooling system and perhaps run a little tighter piston to wall clearance, OR

fill the block with hard-blok and run whatever pistons fit with minimal machine work to the bores? I've seen talk of 2-3cm from the top, with tubes for coolant, but I'm having a hard time picturing this. Are there any photos of this process?

Is there anything else I need to consider/do with the block? It may eventually get to 900-1000hp, but I'm in no rush to see those numbers yet.

The engine went out on a high note, I outran an F1x procharged 2015 viper at a roll race event

https://youtu.be/1tuFK_EGNGc

only have a few pictures right now, perhaps something else jumps out.

(and yes, no roll cage. that's also on the summer project list along with switching to a wagon chassis)