David Vizard, funderingar om låglyftsflöde, överlap m.m.

Postat: mån maj 30, 2011 2:01 pm

taget från speedtalk.com

The Low Lift Flow Controversy

David Vizard Interviewed

By Jake Brown

Graduate Student of the University of Northwestern Ohio

Due to a recent project involvement I had the fortunate opportunity to meet and personally work with David Vizard. My participation in this project involved building, with my partner David Wolfe , a 525 inch Big Block Chevy engine as a dyno test unit for demonstrating the advantages of port and in- cylinder pressure measuring equipment. The purpose of this was to show certain aspects of the induction and exhaust tuning procedures that DV intended to cover during his March 2011 “How to Build Horsepower” seminar. This big block had pressure transducers placed in the intake runner, exhaust runner, and in the combustion chamber for real time running engine pressure graphs. Here I would like to personally thank Clint Gray from TFX Engines for providing us with the equipment and sensors as well as helping us with the final software set up and subsequent dyno runs. I, as well as the University staff and my fellow students greatly appreciate the opportunity given to us by Clint. All those who were working the dyno end of things for the Seminar (about half a dozen of us) found him to be a very enjoyable person to work with and would defiantly recommend him and his company’s products to anyone (http://www.TFXEngine.com" onclick="window.open(this.href);return false;). My partner and I built the 10/1 525 BB Chevy test engine precisely to DV’s instructions and even with nothing more than a hot street cam it cranked out 723 lbs-ft and almost 740 hp. For what was essentially a low buck engine with an idle just under 700 rpm those numbers are pretty impressive and I was really pleased with the fact that I could, along with David Wolfe, lay claim to having built such a power house of an engine.

As for the ‘How to Build Horsepower’ seminar itself I personally found it to be truly amazing. An opinion shared by other Speed Talk subscribers in attendance. I highly recommend DV’s seminars to anyone that has an opportunity to go. Provided with this seminar was David’s new “How to Build Horsepower” book, which can also be purchased on Amazon.com along with his new Big Block Book(which will show readers clearly how to make the pump gas 1.38 LB-FT per cube that ours made without breaking the bank) which should be out by the end of June. You will also see on amozon.com, a bunch of other titles he has written. I cannot vouch for every book David has written but having read about 10 of his books I can say they are the most informative and easy to understand books from any tech writer I have ever read. The new How to Build Horsepower book that was used as the seminar notes has a lot of horsepower generating info on cam timing and valve events that cannot be sourced anywhere else other than DV’s writings (and yes I really do know now why ‘128’ is the most important thing you can know about speccing a cam for a typical V8 motor). The book also has some really good exhaust tuning notes as well, just and overall very good book. That is probably why it is required reading at several prominent Universities if that tells you anything.

After recovering from his grueling 16 hour presentation at the UNOH seminar, I had the opportunity to talk with DV. Here he took time out of his ever busy day to do a one-on-one interview with me over the much debated subject regarding a hot induction cycle topic. The topic in question here concerns the relative merits of low lift flow versus high lift flow and just how it affects the engines output. Yes I asked whether high low lift flow in cylinder heads hurts or aids power, hurts low end, helps high end, and, more to the point, why. As you may have guessed there is more to it than it might at first seem, so, in my words, here is what I got from DV during an interview lasting over 4 hours.

To start things off, when comparing ‘bad low lift flow heads’ versus ‘good low lift flow heads’ there seems to be a trend of just comparing two different heads on the same long block set up and basing the results off of that. In simple terms a basic A versus B test. This however, is an unfair comparison because either way the engine is built, be it with ‘good low lift flow’ heads or ‘bad lift low flow’ heads, the camshaft should have been optimally spec’d for which ever head combination is being used. So, if you take the cylinder heads off and put the opposing cylinder heads on, the cam is now incorrectly spec’d for this new combination that the cylinder will see, and it cannot produce to its full advantage. As DV was quick to point out an engine does not know how far the valve is lifted: it only recognizes how much airflow exists at the crank angle prevailing at that moment. For instance if our engine has 80 degrees of overlap, and intake flow at TDC is X, then the engine sees X amount of airflow not X amount of lift. In other words the flow could be from either an efficient valve at a lower lift or a less efficient valve at higher lift. The engine does not know nor care which of these two situations exists, it cares only that pressure differentials from the exhaust, across the chamber and to the intake are such so as to optimally scavenge the combustion chamber. Now if we make the flow X more or less at any given point during the overlap the cylinder will either under scavenge or over scavenge because it still only sees air flow for any given crank angle during the overlap period. From this it follows that while the overlap used is application dependant (a lot for a race engine and minimal for a tractor engine) the LCA is dictated by the flow per degree of crank rotation during the overlap period not the valve lift. I am hoping here that my explanation is clear enough to make the point but if I am not quite making it (and Lord knows this is not a simple subject) David’s “How to Build Horsepower” book explains this both clearly and in detail but does take a lot more pages than I have room for here to do so.

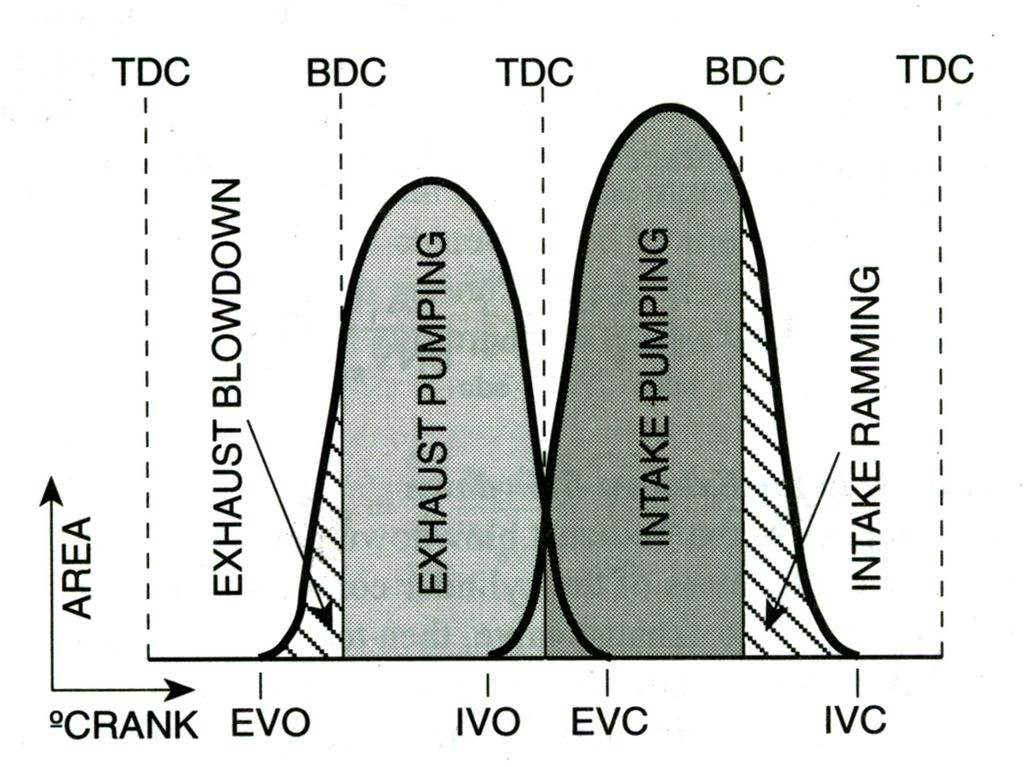

During both his seminar and during my interview with DV one misconceived aspect of the induction cycle was repeatedly stressed. This misconception in many cases proves the hinge point on which the ‘too much flow at low lift is bad’ and the ‘high lift flow matters most because that is when the piston demand is highest theory is based. As DV pointed out and as was demonstrated by the TFX port and in-cylinder pressure demo at DV’s seminar we saw that for the whole induction event , the biggest draw on the intake port was produced by the exhaust pulse scavenging the combustion chamber not on piston travelling down the bore at peak speed. For example, on the demo 525 inch big block Chevy my partner and I built, the TFX pressure instrumentation showed, at TDC, a differential of 11 PSI from the intake runner through the combustion chamber to the exhaust! This broke down to about a 3.5 psi pressure pulse in the intake and a near astonishing 7.5 psi suction from the exhaust. The depression caused by the piston traveling down the bore was a mere 1.5 psi!

As I write this David and Clint are still working on the artwork for these and many other related pressure based experiments they have done or are doing. Much of this stuff was originally intended to be part of David’s BB Chevy engine book volume two which carries on from volume one. Although BB Chevy volume one is about to hit book shops and amazon.com within about 3 to 4 weeks (end of June 2011 latest) volume two is still a couple of years out. This being the case I am pleased to say that I have been able to get David to agree to put the pressure maps concerning this subject and a detailed explanation of the implications up on his website (motortecmagazine.net) which he should have up and running good in the near future.

Back on the subject of piston induced depression. Here David pointed that if the piston depression is more than 20 inches of water, which is around - .7 PSI, then the head(s) need to flow more air for the cubes/rpm combination being used. So if one were to run a head with ‘bad low lift flow’ the opportunity of taking full advantage of one of the most critical aspects of induction and exhaust tuning would be substantially lost. If the maximum advantage of pressure pulse and inertial tuning is actively sought then it will be seen that low lift flow is vital. As DV so aptly demonstrated air is considerably heavier than 99.99% of the performance community thinks it is. From this it also stems that port velocity is also more important than 99.99% of the performance community think it is.

Also playing a role here is the fact that any lift less than peak valve lift happens twice in a cycle where as the flow at max valve lift happens only once. So now we see that the start to our induction cycle and the end ramming effect for more trapped mass is dependent on a cylinder head’s ‘low lift flow’. The late Smokey Yunick reinforced the fact that lower valve lift flows are to be focused on because they are used twice in a cycle.

Another misleading aspect(and one that is touted by some very respected University book reading) is that the intake valve closure point is the most important and influential valve event in the event cycle. Using the pressure traces from the TFX gear and our dyno tests DV quickly shot that assumption to ribbons. Using the pressure data he demonstrated that it is vital, for an optimal induction cycle, to get it right in the first (opening) half. He also showed from this that if the first part of the induction cycle was not optimal there was no possible way to make a full redemption in the second half. This again was a pointer to the fact that strong low lift flow is a prime requirement if the best volumetric efficiencies are to be seen. Although relegated from the number one spot the intake valve closure point is still important if the most of inertial ramming of the cylinder is to be made. However DV was adamant that no matter when the intake was closed it could never compensate for incorrect event timing during the overlap period. For what it is worth DV also pointed out that the 5 hp per cube outputs of current F1 engines are largely due to low lift flow per cube figures as much as three times that of a current cup car engine.

Another issue though more minor in nature seems also to be entwined with the low lift flow arguments is that a cylinder head with really good ‘low lift flow’ sacrifices ‘high lift flow’. Due to our knowledge of ports and valve seats gleaned from any one of a number of big Superflow flow benches at the university even my own testing has found that to be not entirely true. Achieving above average low lift flow may hurt a fraction of high lift flow but not necessarily kill it to the point of offsetting any possible gains from the better low lift flow. As we discussed in the above, the advantages of flowing better at lower valve lifts far outweigh the odd CFM or so that might be lost at high lift.

Here David outlined one of his research projects done many years ago while working on the 2 liter Pinto engine. With the induction (twin side draft 45 DCOE Webbers) and exhaust dimensions held constant he used two different heads on the test engines long block. The first of these was one of DV’s own super ported two valve factory iron heads which we will call head A. The intake flow for this head was a little over 150 cfm at 0.250 lift and 218 at 0.650 lift.

Head B was a near stock Cosworth 4 valve head which delivered almost 190 cfm at 0.250 lift and 214 cfm at 0.500 lift After testing the two valve head the 4 valve head was cammed such that it delivered the same torque at 3000 rpm. The tests showed the greater ‘low lift flow head’ (B) even with slightly less peak flow achieved about 30 HP gain over Head A. In case you might think this an isolated instance DV also has some extensive tests with domestic small block V8’s. but it’s not my place here to go publishing all the results of tests done with the intent to use it in articles and books he is going to write.

Tests done with the TFX gear during DV’s seminar at UNOH and the dyno results put forward along with DV’s explanations has left no doubt in my mind that good low lift flow is the performance engine builders friend not, as seems so often to be believed his enemy. I would also like to point out that the arguments for such are based on hard core testing not personal opinions. As such they are not intentional attacks on those with contrary views but in the light of current test data it might be a good idea to re-think any possible counter arguments. Which, if you feel you want to discuss anything I have said here brings me to my final point. At this moment in time Goodson and Myron Cottrell of TPI Specialties are negotiating with DV to do a streamlined two day version of the 3 day ‘How to Build Horsepower’ UNOH seminar he did back in March. Details will be posted on Davidvizardseminars.com.

If all goes well, and there is no reason to suppose it won’t, this should happen about mid September 2011. If you want to get a really good idea of what will be covered then go to Amazon.com and order yourself a copy of DV’s book. I can personally tell you there’s so much to be learned from this man.

The Low Lift Flow Controversy

David Vizard Interviewed

By Jake Brown

Graduate Student of the University of Northwestern Ohio

Due to a recent project involvement I had the fortunate opportunity to meet and personally work with David Vizard. My participation in this project involved building, with my partner David Wolfe , a 525 inch Big Block Chevy engine as a dyno test unit for demonstrating the advantages of port and in- cylinder pressure measuring equipment. The purpose of this was to show certain aspects of the induction and exhaust tuning procedures that DV intended to cover during his March 2011 “How to Build Horsepower” seminar. This big block had pressure transducers placed in the intake runner, exhaust runner, and in the combustion chamber for real time running engine pressure graphs. Here I would like to personally thank Clint Gray from TFX Engines for providing us with the equipment and sensors as well as helping us with the final software set up and subsequent dyno runs. I, as well as the University staff and my fellow students greatly appreciate the opportunity given to us by Clint. All those who were working the dyno end of things for the Seminar (about half a dozen of us) found him to be a very enjoyable person to work with and would defiantly recommend him and his company’s products to anyone (http://www.TFXEngine.com" onclick="window.open(this.href);return false;). My partner and I built the 10/1 525 BB Chevy test engine precisely to DV’s instructions and even with nothing more than a hot street cam it cranked out 723 lbs-ft and almost 740 hp. For what was essentially a low buck engine with an idle just under 700 rpm those numbers are pretty impressive and I was really pleased with the fact that I could, along with David Wolfe, lay claim to having built such a power house of an engine.

As for the ‘How to Build Horsepower’ seminar itself I personally found it to be truly amazing. An opinion shared by other Speed Talk subscribers in attendance. I highly recommend DV’s seminars to anyone that has an opportunity to go. Provided with this seminar was David’s new “How to Build Horsepower” book, which can also be purchased on Amazon.com along with his new Big Block Book(which will show readers clearly how to make the pump gas 1.38 LB-FT per cube that ours made without breaking the bank) which should be out by the end of June. You will also see on amozon.com, a bunch of other titles he has written. I cannot vouch for every book David has written but having read about 10 of his books I can say they are the most informative and easy to understand books from any tech writer I have ever read. The new How to Build Horsepower book that was used as the seminar notes has a lot of horsepower generating info on cam timing and valve events that cannot be sourced anywhere else other than DV’s writings (and yes I really do know now why ‘128’ is the most important thing you can know about speccing a cam for a typical V8 motor). The book also has some really good exhaust tuning notes as well, just and overall very good book. That is probably why it is required reading at several prominent Universities if that tells you anything.

After recovering from his grueling 16 hour presentation at the UNOH seminar, I had the opportunity to talk with DV. Here he took time out of his ever busy day to do a one-on-one interview with me over the much debated subject regarding a hot induction cycle topic. The topic in question here concerns the relative merits of low lift flow versus high lift flow and just how it affects the engines output. Yes I asked whether high low lift flow in cylinder heads hurts or aids power, hurts low end, helps high end, and, more to the point, why. As you may have guessed there is more to it than it might at first seem, so, in my words, here is what I got from DV during an interview lasting over 4 hours.

To start things off, when comparing ‘bad low lift flow heads’ versus ‘good low lift flow heads’ there seems to be a trend of just comparing two different heads on the same long block set up and basing the results off of that. In simple terms a basic A versus B test. This however, is an unfair comparison because either way the engine is built, be it with ‘good low lift flow’ heads or ‘bad lift low flow’ heads, the camshaft should have been optimally spec’d for which ever head combination is being used. So, if you take the cylinder heads off and put the opposing cylinder heads on, the cam is now incorrectly spec’d for this new combination that the cylinder will see, and it cannot produce to its full advantage. As DV was quick to point out an engine does not know how far the valve is lifted: it only recognizes how much airflow exists at the crank angle prevailing at that moment. For instance if our engine has 80 degrees of overlap, and intake flow at TDC is X, then the engine sees X amount of airflow not X amount of lift. In other words the flow could be from either an efficient valve at a lower lift or a less efficient valve at higher lift. The engine does not know nor care which of these two situations exists, it cares only that pressure differentials from the exhaust, across the chamber and to the intake are such so as to optimally scavenge the combustion chamber. Now if we make the flow X more or less at any given point during the overlap the cylinder will either under scavenge or over scavenge because it still only sees air flow for any given crank angle during the overlap period. From this it follows that while the overlap used is application dependant (a lot for a race engine and minimal for a tractor engine) the LCA is dictated by the flow per degree of crank rotation during the overlap period not the valve lift. I am hoping here that my explanation is clear enough to make the point but if I am not quite making it (and Lord knows this is not a simple subject) David’s “How to Build Horsepower” book explains this both clearly and in detail but does take a lot more pages than I have room for here to do so.

During both his seminar and during my interview with DV one misconceived aspect of the induction cycle was repeatedly stressed. This misconception in many cases proves the hinge point on which the ‘too much flow at low lift is bad’ and the ‘high lift flow matters most because that is when the piston demand is highest theory is based. As DV pointed out and as was demonstrated by the TFX port and in-cylinder pressure demo at DV’s seminar we saw that for the whole induction event , the biggest draw on the intake port was produced by the exhaust pulse scavenging the combustion chamber not on piston travelling down the bore at peak speed. For example, on the demo 525 inch big block Chevy my partner and I built, the TFX pressure instrumentation showed, at TDC, a differential of 11 PSI from the intake runner through the combustion chamber to the exhaust! This broke down to about a 3.5 psi pressure pulse in the intake and a near astonishing 7.5 psi suction from the exhaust. The depression caused by the piston traveling down the bore was a mere 1.5 psi!

As I write this David and Clint are still working on the artwork for these and many other related pressure based experiments they have done or are doing. Much of this stuff was originally intended to be part of David’s BB Chevy engine book volume two which carries on from volume one. Although BB Chevy volume one is about to hit book shops and amazon.com within about 3 to 4 weeks (end of June 2011 latest) volume two is still a couple of years out. This being the case I am pleased to say that I have been able to get David to agree to put the pressure maps concerning this subject and a detailed explanation of the implications up on his website (motortecmagazine.net) which he should have up and running good in the near future.

Back on the subject of piston induced depression. Here David pointed that if the piston depression is more than 20 inches of water, which is around - .7 PSI, then the head(s) need to flow more air for the cubes/rpm combination being used. So if one were to run a head with ‘bad low lift flow’ the opportunity of taking full advantage of one of the most critical aspects of induction and exhaust tuning would be substantially lost. If the maximum advantage of pressure pulse and inertial tuning is actively sought then it will be seen that low lift flow is vital. As DV so aptly demonstrated air is considerably heavier than 99.99% of the performance community thinks it is. From this it also stems that port velocity is also more important than 99.99% of the performance community think it is.

Also playing a role here is the fact that any lift less than peak valve lift happens twice in a cycle where as the flow at max valve lift happens only once. So now we see that the start to our induction cycle and the end ramming effect for more trapped mass is dependent on a cylinder head’s ‘low lift flow’. The late Smokey Yunick reinforced the fact that lower valve lift flows are to be focused on because they are used twice in a cycle.

Another misleading aspect(and one that is touted by some very respected University book reading) is that the intake valve closure point is the most important and influential valve event in the event cycle. Using the pressure traces from the TFX gear and our dyno tests DV quickly shot that assumption to ribbons. Using the pressure data he demonstrated that it is vital, for an optimal induction cycle, to get it right in the first (opening) half. He also showed from this that if the first part of the induction cycle was not optimal there was no possible way to make a full redemption in the second half. This again was a pointer to the fact that strong low lift flow is a prime requirement if the best volumetric efficiencies are to be seen. Although relegated from the number one spot the intake valve closure point is still important if the most of inertial ramming of the cylinder is to be made. However DV was adamant that no matter when the intake was closed it could never compensate for incorrect event timing during the overlap period. For what it is worth DV also pointed out that the 5 hp per cube outputs of current F1 engines are largely due to low lift flow per cube figures as much as three times that of a current cup car engine.

Another issue though more minor in nature seems also to be entwined with the low lift flow arguments is that a cylinder head with really good ‘low lift flow’ sacrifices ‘high lift flow’. Due to our knowledge of ports and valve seats gleaned from any one of a number of big Superflow flow benches at the university even my own testing has found that to be not entirely true. Achieving above average low lift flow may hurt a fraction of high lift flow but not necessarily kill it to the point of offsetting any possible gains from the better low lift flow. As we discussed in the above, the advantages of flowing better at lower valve lifts far outweigh the odd CFM or so that might be lost at high lift.

Here David outlined one of his research projects done many years ago while working on the 2 liter Pinto engine. With the induction (twin side draft 45 DCOE Webbers) and exhaust dimensions held constant he used two different heads on the test engines long block. The first of these was one of DV’s own super ported two valve factory iron heads which we will call head A. The intake flow for this head was a little over 150 cfm at 0.250 lift and 218 at 0.650 lift.

Head B was a near stock Cosworth 4 valve head which delivered almost 190 cfm at 0.250 lift and 214 cfm at 0.500 lift After testing the two valve head the 4 valve head was cammed such that it delivered the same torque at 3000 rpm. The tests showed the greater ‘low lift flow head’ (B) even with slightly less peak flow achieved about 30 HP gain over Head A. In case you might think this an isolated instance DV also has some extensive tests with domestic small block V8’s. but it’s not my place here to go publishing all the results of tests done with the intent to use it in articles and books he is going to write.

Tests done with the TFX gear during DV’s seminar at UNOH and the dyno results put forward along with DV’s explanations has left no doubt in my mind that good low lift flow is the performance engine builders friend not, as seems so often to be believed his enemy. I would also like to point out that the arguments for such are based on hard core testing not personal opinions. As such they are not intentional attacks on those with contrary views but in the light of current test data it might be a good idea to re-think any possible counter arguments. Which, if you feel you want to discuss anything I have said here brings me to my final point. At this moment in time Goodson and Myron Cottrell of TPI Specialties are negotiating with DV to do a streamlined two day version of the 3 day ‘How to Build Horsepower’ UNOH seminar he did back in March. Details will be posted on Davidvizardseminars.com.

If all goes well, and there is no reason to suppose it won’t, this should happen about mid September 2011. If you want to get a really good idea of what will be covered then go to Amazon.com and order yourself a copy of DV’s book. I can personally tell you there’s so much to be learned from this man.